LIFTING AND RIGGING ACCESSORIES

It is important to know that not all rigging hardware is suitable for overhead lifting. For example, rigging equipment used for securing loads, towing, and lashing may not be suitable for vertical lifting, which involves significantly higher stresses and demands greater safety margins and more robust equipment.

When selecting rigging equipment for lifting, be sure that it is rated for overhead lifting.

Selecting Appropriate Rigging Equipment

When selecting rigging equipment, be sure that the equipment’s rated capacity (RC) or working load limit (WLL) is suitable for the intended application. WLLs are affected by the equipment’s material and design. For more information about how rigging hardware is rated, take a look at What is Rigging Hardware and How is it Rated?

WLL—which may also be expressed as RC—is a calculated value that accounts for the equipment’s minimum breaking load (MBL) and a safety factor (SF).

WLL = MBL/SF

The safety factor is essential because it is challenging for riggers to account for every possible variable that might impact the load a piece of equipment experiences. The safety factor provides a margin of error. It should not be considered as reserve strength available to accommodate additional loading.

RC and WLL figures are calculated for straight zero-degree loading. However, if the load is applied at an angle, the WLL is significantly reduced. For example, a lifting eye bolt with a WLL of 1,000 lbs for a zero-degree lift has a working load limit of 400 lbs if the load is applied at 30° from the vertical and 220 lbs if applied at 60°.

When selecting rigging hardware such as hooks, shackles, and eye nuts or eye bolts, ensure that the hardware has a WLL appropriate to the load and that it matches or exceeds the WLL of the wire rope or chain being used.

Please note that WLLs do not apply if the hardware experiences shock loading. Shock loading through sudden load movement can generate forces that exceed the WLL, so it’s vital to avoid rapid changes in speed or direction while moving heavy loads.

Rigging and Equipment Inspection

All rigging and lifting equipment should be inspected before use to ensure that it is undamaged. The Occupational Safety and Health Administration (OSHA) says that equipment should be “inspected prior to use on each shift and as necessary during its use to ensure that it is safe.” If the equipment is damaged in any way, it should be withdrawn from service immediately.

Rigging Hardware Suitable for Vertical Lifting

Rigging equipment, including rigging hardware suitable for overhead lifting. The following is an overview of the types of lifting equipment we stock and how it is used.

Rigging Master Links

Master links are closed-loop end fittings typically deployed with chain slings, wire rope slings, and hooks. They are available in two main types:

- Oblong Master Links feature longer parallel straight sections with curved ends that form a closed link. They make it quick and easy to attach slings to hooks or end links.

- Pear‑Shaped Master Links feature a narrow end and a wide end to accommodate different sizes of hooks, including hooks that have a narrow saddle.

Our master links are weldless for improved strength and are ideal for use with large hooks and shackles.

Lifting Eye Bolts

Eye bolts feature a threaded shank attached to a circular eye or ring into which a shackle wire rope eye can be attached. Eye bolts exposed to angled forces must also include a shoulder or collar. Eye bolts without a collar can break under angled loads, so they are only appropriate for zero-degree inline loads.

During lifting operations, the eye bolt is screwed into a threaded hole or ferrule on the load so that the shoulder is tightly secured to, flush with, and fully seated against the surface of the load. They are then attached to slings and chains via a shackle. As explained in Best Practices When Using Lifting Eye Bolts, eye bolts should not be attached directly to hooks. Additionally, the eye bolt’s shank should not contact the bottom of the threaded bore into which it is screwed.

We stock a variety of lifting eye bolts, including DIN Standard Eye Bolts and Shoulder Pattern Lifting Eye Bolts. We also stock Plain Pattern Lifting Eye Bolts, which are only suitable for zero-degree vertical lifts.

Lifting Eye Nuts

Eye nuts feature a female-threaded nut with an eye that accommodates a shackle. In use, the nut is screwed onto a threaded shank on the load. Eye nuts form a similar attachment to an eye bolt, except that the threaded shank is attached to the equipment instead of being integrated into the rigging equipment.

As with eye bolts, if you plan to use lifting eye nuts in scenarios in which they receive angular loads, be sure to select eye nuts with a collar or shoulder. Additionally, the threaded shank onto which the eye nut is screwed must be shorter than the eye nut’s bore.

We stock several varieties of lifting eye nuts, including:

- Standard Lifting Eye Nuts and Heavy-Duty Eye Nuts suitable for zero-degree or in-line loads. These eye nuts do not include a shoulder and should not be loaded at an angle.

- DIN Standard Eye Nuts are shouldered eye nuts. They are ideal for a wide range of lifting, rigging, and lashing operations. As with all lifting equipment, their WLL is significantly reduced under angled loads.

Lifting Shackles

A shackle is a load-bearing rigging component with a curved body terminated by holes through which a pin or bolt is inserted. The shackle’s pin may be a screw pin, bolt pin, or a round pin secured in place by a cotter pin. Their main role is to connect other rigging equipment. For example, a shackle’s pin may be inserted into the eye of a lifting eye bolt fixed to a piece of heavy equipment. A hook connected to a sling can then be inserted through the shackle’s body.

Lifting shackles are available in two main varieties:

- Anchor or Bow Shackles have a circular body. These shackles are suitable for angular loads provided the pin experiences a straight load and the bow experiences the angular load.

- Chain or D-Ring Shackles have a narrower body that can hold a heavier load than an equivalent anchor shackle. However, chain and D-link shackles are not suitable for angled loads. Instead, the load should align with the shackle’s centerline.

Several attributes determine a shackle’s suitability. In addition to the RC, shackles should be selected with the correct pin diameter for the attachment point and an inside bow height and diameter that provides sufficient clearance for the chain or hook. Shackles should only be used with the supplied shackle pin to ensure the pin’s WLL or RC are suitable for the load and that the threads on the pin and body are compatible.

Positioning Swivels

Positioning swivels are two-way rigging attachments that permit both connected components to rotate when the swivel is not under load. They allow for rotational adjustment, positioning and alignment, and prevent the twisting of chains or wire ropes. Once the swivel is placed under load during a lift, it is locked in position, and the two components cannot rotate relative to each other.

Swivels are available in two basic styles, depending on the type of attachment they provide.

- Eye-Eye Swivels feature a pair of eye attachments that can be connected to shackles and hooks.

- Jaw-Eye Swivels feature one eye and one jaw attachment. The jaw end has a similar design to a clevis or yoke end, with a clevis pin inserted through the ears of the jaw and typically secured by a shoulder at one end and a cotter pin at the other. Jaw ends allow for quick connections and disconnection from other components by simply removing the cotter pin and pulling the clevis pin. Jaw ends should be used with the supplied clevis pin to ensure it correctly fits the body and has an adequate WLL or RC.

Swivels are suitable only for zero-degree lifting applications.

Rigging Hardware for Pulling, Towing, Lashing, and Anchoring

Chains and Chain Hardware

Chain is a durable and flexible rigging component with many applications in construction, agriculture, transport, and other industries. The strength of a length of chain is indicated by its grade, which reflects its design and materials.

grades of chain:

- Grade 30 Chain, also known as proof coil chain, is made of low-strength carbon steel. It is a lightweight and economical chain for securing loads, lashing cargo, and as guard rails.

- Grade 70 Chain, also known as transport chain, is a heavier chain made of heat-treated carbon steel. As you might expect from its name, transport steel is the standard in the transportation industry, where it’s used for tie-downs and lashings, for towing, and as a safety chain. Transport chain is typically yellow in color due to its zinc yellow chromate finish, making it easy to identify.

Note that Grade 30 and Grade 70 chains are not suitable for overhead lifting. For overhead lifting applications, use an alloy steel chain of Grade 80 or higher.

In addition to lengths of chain, you may need hardware to link chains together, to other equipment, or to replace damaged chain links. Rigging equipment of this type includes:

- Cold Shuts are used to repair chains quickly and to attach other hardware. They can be installed in the field with a hammer. Cold shuts feature an eye at one end through which the other end is hammered before being peened to prevent unfastening.

- Quick Links are link-shaped components with a gap that can be bridged by a gate that fixes to a threaded segment.

- Repair Lap Links are open links that can be closed with a hammer or vice. They are easy to fit and re-open with hand tools.

- A double link—also known as a Double Clevis or twin clevis—is a connector with clevis links at either end. They often provide an attachment point for chains and rigging equipment such as hooks and eye bolts. Double clevises can also repair broken chains in the field. Double clevises are made of carbon steel and are intended for use with Proof Coil Chain; they should not be used for overhead lifting. Ensure that the WLL or RC of the double clevis meets or exceeds that of the chain it is used with.

- Snap Hooks, or spring snap links, are equipped with a self-closing gate across the throat to securely hold a chain and prevent it from slipping from the throat. As a result, snap hooks are ideal for quick installation for coupling and anchoring applications. Snap links are a convenient solution for light-duty rigging and lashing applications.

When using cold shuts, quick links, or lap links, ensure that they have a RC or WLL at least as high as the chain to which they are attached. None of these shuts or links are appropriate for overhead lifting.

Turnbuckles

Turnbuckles, sometimes called bottlescrews, add tension or adjust the chain or wire rope length. Turnbuckles include a pair of rods with opposing threads that screw into a frame. Rotating the frame draws the rods together or pushes them apart, tensioning or slackening attached components and rigging hardware.

The simplest turnbuckles resemble a pair of eye bolts screwed into the frame. But turnbuckles are available with many different attachments, including eyes, hooks, shackle-like jaws, and stubs or rod ends with a partially threaded rod with an unthreaded stub end to which you can fasten various attachments.

You can choose a different attachment for each end, creating a wide variety of combinations, including:

- Eye‑Eye Turnbuckles

- Hook‑Eye Turnbuckles

- Hook‑Hook Turnbuckles

- Jaw‑Eye Turnbuckles

- Jaw‑Jaw Turnbuckles

- Stub‑Stub Turnbuckles

Hooks

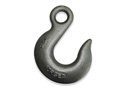

Hooks attach either to the load or to shackles and other rigging hardware. They are available in many varieties, each designed for a particular use case.

Grab Hooks have a straight, narrow throat that is designed to “grab” a chain link. This prevents the chain from slipping freely through the hook. Grab hooks are typically used to shorten or hold a length of chain and for pulling and towing heavy loads in the transport, oil and gas, and logging industries.

Grab hooks are available with eye attachments for permanent installation and clevis attachments for easy installation and removal.

Slip Hooks feature a wide throat that allows chain and wire rope to move freely. Unlike grab hooks, slip hooks make it easy to adjust the hook’s position on a length of chain when lashing and securing loads. As with grab hooks, slip hooks are available with both eye and clevis attachments.

Wire Rope Hardware

Wire rope is an alternative to chain in rigging operations. It is made of a natural or synthetic fiber or steel core wrapped in helically arranged wire strands. It can be used in many applications in place of chain, including towing, hoisting, mooring, lashing, and securing loads.

wire rope hardware accessories and clips, including:

- Wire Rope Clips, or U-bolt cable clamps, are a convenient and economical choice to create cable splices or wire rope eyes in the field with common hand tools. Single-saddle wire rope clips can loosen over time and should be inspected and retightened periodically to ensure they remain fit to be in service.

- Fist Grip Clips, or double-saddle wire rope clips, are similar to wire rope clips but are simpler to install and provide more resistance to loosening in the field. Fist Grip Clips should still be inspected periodically to detect any loosening while in service.

- Wire Rope Sleeves, also known as swage sleeves or cable crimps, are commonly used to form loop ends or wire splices. Wire rope sleeves are generally preferable to wire rope clips because they tend not to loosen or require retightening and are intended for permanent installation since they cannot be reused.

- Wire Rope Thimbles provide a durable wear surface for connecting loops of wire rope, also known as wire rope eyes, to other rigging equipment. In addition to protecting rope from abrasion, thimbles prevent the eye from bending too tightly when under load by distributing the load’s forces over a larger area.

- Wire Rope Rings are welded carbon steel rings that, among other uses, can act as an attachment point for wire rope and cables, as well as a closure for securing lashing straps.

Clevis Yoke, Adjustable Yoke, and Rod End Fittings

Clevis Rod Ends, or clevis ends, are a type of clevis shackle with a tapped hole into which a threaded rod can be screwed. Clevis rod ends provide an attachment point for chains and wire ropes that can be quickly installed or removed.

Adjustable Yoke End Fasteners, which are also called yoke clevises, are similar to clevis rod ends and are used in many comparable rigging scenarios. However, yoke ends have a fixed grip range—the gap between the two arms of the jaw through which the clevis pin is inserted—while clevis ends are more customizable.

The main difference between clevis ends and yoke ends is that the grip of the clevis can be specified to suit the application, whereas yoke end fittings have a fixed width ratio to the equipment’s length. Yoke ends are an inexpensive alternative to clevis ends, although they are less flexible.

A Rod End Bolt is a threaded shaft with an eye at one end. The shaft can be attached to a mating tapped hole, and the eye can be used as an attachment point for other rigging equipment. Rod ends can be deployed in many of the same scenarios as an eye bolt or as an eye end in a turnbuckle assembly. Rod ends can also create hinges or pivot points in rigging setups or tie-down points for securing loads.